Engines are crucial to how well a car runs overall, and font engines are perhaps the most prevalent, accounting for over 98% of all vehicles.

The engine block is the foundation of the vehicle’s powertrain and is frequently built of aluminum or iron, although some other types of engines are installed in vehicles in different ways.

The Vortec line of engines was designed for GM’s SUV and truck lines, while engines with the LS designation were primarily built for use in passenger cars.

Early LS1s required additional cap fasteners to keep the slightly flexible block in place, while later LS3 and iron LS platforms were propelled to god-like status by the rigid bottom-end design’s Herculean strength.

Keep reading to know more about the engines in a car, and how a Vortex Engine differs from an LS Engine. Let’s begin!

Types of LS Engines

There are about 40 different LS engine flavors, ranging from 255 horsepower 4.8-liter donks to 650+ horsepower 6.2-liter powerhouses, and that’s before taking into account aftermarket choices. These include the LS1, LSX, LSA, LS2, and LS9 engines.

The aforementioned engines can be categorized into different generations of engines ranging from 1997-2017, and above.

| Types of LS Engines | Description |

| Gen III | It spans the years 1997 to 2008 and includes the truck-based 6.0L LQ9 and a slew of other meaningless engines in Australia, such as the 5.7L LS1. |

| Gen IV | The 6.0L LS2 and 6.2L LS3, the supercharged 6.2L LSA, and roughly 20 other variations that you’ll never see here are all products of this generation, which spans 2007 to 2017. |

| Gen V | The Gen V, which comprises a large number of Corvette engines we will never obtain, was introduced in 2014 and beyond. |

Don’t bother trying to understand any of the numbers because Gen III goes up to 345hp, 6.0 liters, and Gen IVs go down to 260hp, 4.8 liters.

Difference Between A Vortec And An LS Engine

Over the years, GM truck engines have simply gone by the name Vortec. Given that this designation was applied to such a wide range of engines, it indicates very little to nothing about the engines themselves.

The Atlas family of DOHC inline 4, 5, and 6-cylinder engines, the LS-based truck engines, and the Gen I classic small block engines (think vintage “Chevy 350”) are among the engines with the Vortec designation.

LS car engines and LS-based truck engines are quite similar. However, they frequently feature lower compression ratios, alternative intake manifolds, and cast iron blocks.

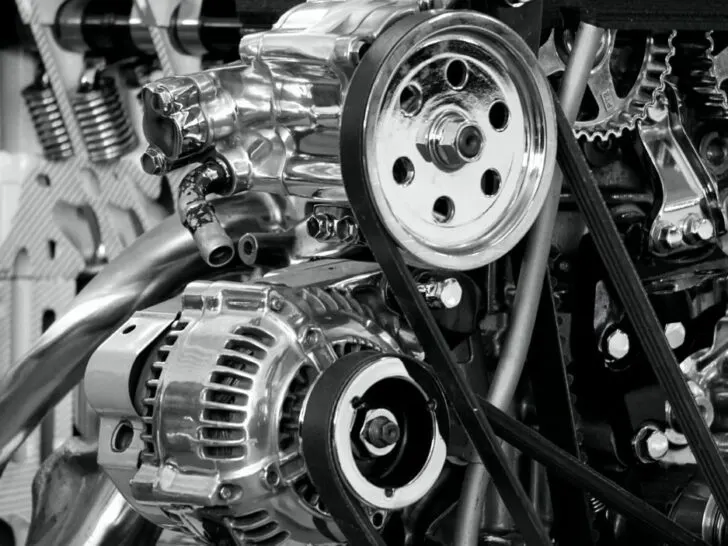

The crank bearing caps on LS engines are flush with the oil pan gasket surface, and all varieties employ four bolts to secure each cap as opposed to two or four in prior SBC engines.

The water pump has a different depth and form from the timing cover. The bracketry for the accessory drive includes the factory LS water pump.

Instead of the cam-driven oil pumps seen on previous SBC engines, LS engines have a crank-driven oil pump placed behind the timing cover.

However, the SBC exhaust port spacing, which had the two center ports close together, was still present in the cast iron Vortec engines.

The Vortec’s intake manifold was built to work with GM’s two-barrel throttle body fuel injection system, while a multiport system was an option for high-performance applications.

What is so Special About a Vortec Engine?

- Durability and Reliability: Vortec engines are designed to be solid and dependable, providing long-lasting performance. To guarantee the longevity of these engines, GM has invested in quality control and technical methods.

- Versatility: A variety of vehicles, including trucks, SUVs, and even passenger cars, have been fitted with Vortec engines. They are made to have sufficient low-end torque, which makes them ideal for applications that call for the ability to pull and haul.

How Can You Identify a Vortec Engine?

A Vortec engine may be recognized by checking for specific identifying characteristics. Here are a few indicators that are frequently used to identify Vortec engines:

- Engine Badging: To identify a Vortec engine, many vehicles with Vortec engines may have badges or stickers on the engine cover. Keep an eye out for labels that say “Vortec” or reference a particular engine, such as “Vortec 5.3L” or “Vortec 6.0L.”

- Casting Numbers: The engine block or cylinder heads of Vortec engines frequently feature distinctive casting numbers. These numbers, which are often alphanumeric codes that give details on the engine type and specs, may be found on the engine itself.

Alternatives To Vortec And LS Engines

Internal Combustion Engine

They run everything from vehicles to helicopters to lawnmowers. The largest IC engine can propel a ship carrying 20,000 containers with 109,000 HP.

Fuel is burned inside a specialized component of the system called a combustion chamber to produce energy for IC engines. The volume of the reaction products produced by combustion is significantly more than the combined volume of the reactants.

The heart and soul of IC engines is this expansion; it is what generates motion.

External Combustion Engine

By burning fuel in one chamber and heating the working fluid inside the engine through a heat exchanger or the engine’s wall, it keeps the fuel and exhaust products separate.

EC engines operate somewhat similarly to their IC counterparts in that they both need heat produced by burning materials. But there are also quite a few variations.

The fluids used in EC engines go through thermal dilation-contraction or a phase shift, but their chemical makeup is unaffected. The substance that is employed might either be gaseous, liquid, or change phases.

Conclusion

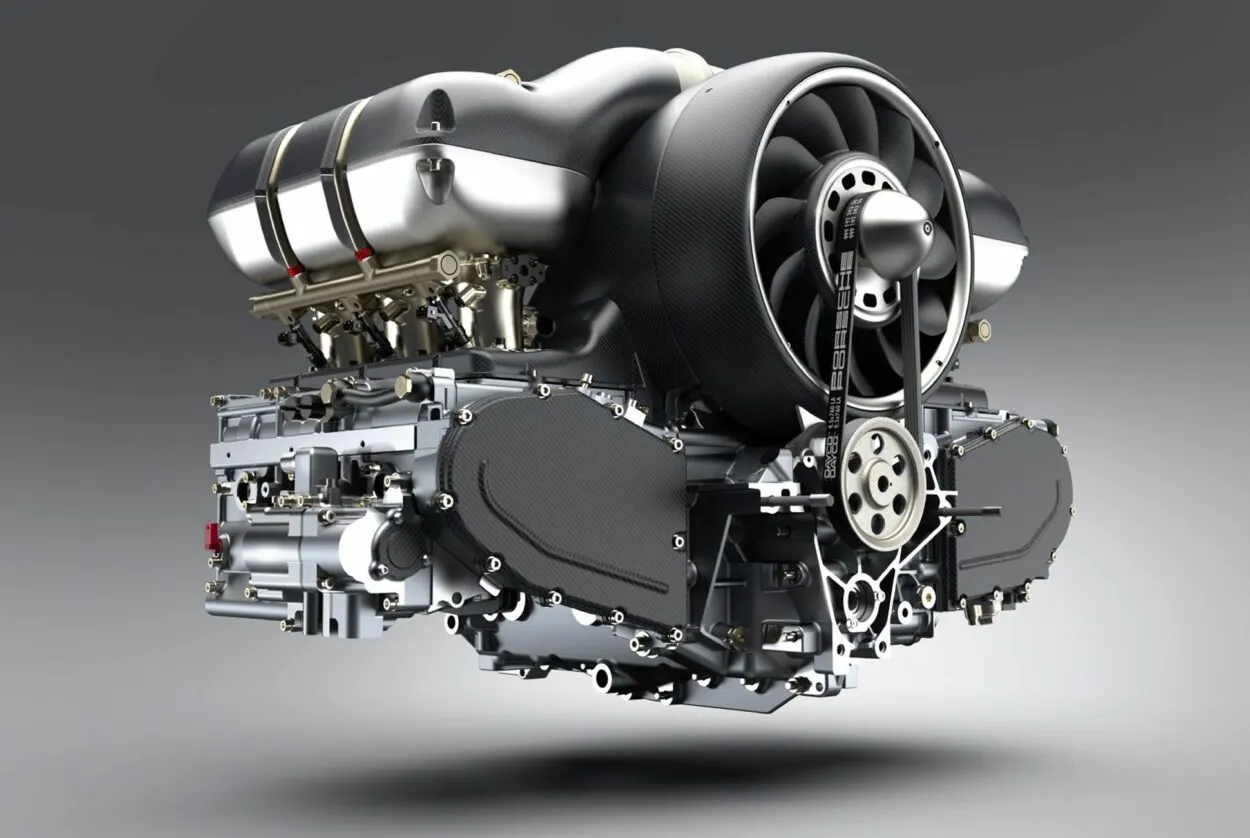

- Pushrod V8s with aluminum cylinder heads are the only type of LS engine. LS-based motors are also seen in the iron-block Vortec series late-model truck engines (1999 and newer).

- Small blocks, which are what LS engines are known as might have an aluminum or an iron block. Although some, like the LSX 454 crate engine, have a big-block displacement. The LS engine comes in two distinct generations, Gen III and Gen IV.

- Electronic fuel injection is used in LS engines. Direct injection is currently present in new Gen V LT engines. They also have 6 bolt main bearing caps and a coil-over-plug ignition system rather than a distributor.

- Performance, fuel economy, durability, and low maintenance were all priorities in the creation of the Vortec engines. To improve the air-to-fuel ratio during combustion, GM engineers used vortex physics in their engines. The Vortec engines were developed as a result of this research’s efforts to boost horsepower without sacrificing efficiency.

- A range of GM truck piston engines carries the trademark Vortec. It was first applied to a 4.3 L V-6 in 1986, but it is now used to describe a variety of engines. The more recent naming scheme uses the approximate cubic centimeter displacement of Vortec engines to call them.